- Category:

- News

Myth busting battery electric vehicle lifecycle emissions

As with any new technology, there are always fears and misconceptions about how it works and the impact it will have.

Over the years, there have been three key claims made by electric vehicle sceptics to challenge each stage of the EV lifecycle.

If true, these would undermine the environmental benefit of EVs, therefore it is important to take a closer look at each and make sure we are asking the right questions.

Claim 1: Manufacturing

The manufacturing of EV batteries is so energy intensive that the EV already has a level of embedded emissions that will never be overcome during operation.

At what point does an EV become more a lower-emission alternative than traditional internal combustion engine vehicles when accounting for the energy required for battery production?

Claim 2: Operation

EVs are powered by the electric grid. As the grid is coal powered, EV’s are actually causing higher emissions that ICEs.

How does the electricity grid generation mix affect the emissions generated for charging in the operational phase of the EV?

Claim 3: End of Life

EV batteries do not last and disposing of them is an environmental disaster waiting to happen

At what rate do EV batteries degrade, and what happens to them once they are no longer useable?

When we move away from unsubstantiated claims and towards more scientific questioning, it is important to consider the environmental impact of EVs on a lifecycle basis to make comparisons with other technologies.

In essence, the three questions above can be joined into a single question:

Do Electric Vehicles produce less CO2 emissions over their lifetime, when factoring in manufacturing, operation and end of life?

Battery Electric Vehicles are a form of zero emission transport, meaning that there are no tailpipe emissions at the point of use. While this is beneficial for improving local air quality, it is imperative to consider the total emissions created during the manufacture, operation and end of life of a vehicle. This is known as a life cycle assessment (LCA), something Cenex conduct on a regular basis.

The Answer

At the manufacturing stage, it is true that the mining of materials and the production of lithium-ion batteries for EVs is energy intensive.

While it is important to remember that internal combustion engine vehicle drivetrains are not without their own embedded emissions, it is true that EVs have greater embedded emissions in the manufacturing stage.

The difference depends on a number of factors:

- The battery capacity – a larger capacity battery will require more energy to manufacture.

- The location – a battery manufactured in a county with a high grid carbon intensity (e.g. Poland – 0.846 kgCO2/kWh) will have massively higher embedded emissions than if manufactured in a country with low grid carbon intensity (e.g. Norway – 0.011 kgCO2/kWh).

- The battery chemistry, design and manufacturing process will also influence the embedded battery manufacturing emissions.

In operation, an EV is not truly zero emission unless it is charged with energy from zero-carbon generation such as renewable sources like wind and solar power.

In the UK, the electricity grid has seen a period of sustained reduction in carbon intensity with coal power generation being phased out in favour of wind, solar and natural gas (still a greenhouse gas but with a lower emission factor than coal).

In 2018, Transport overtook Energy as the largest emitting sector in the UK and renewable generation records continue to be broken – in 2020 the renewables overtook fossil fuels as the main source of energy, with 42% of the total generation.

Therefore, as with manufacturing, where the vehicle is operated will play a large role in the lifecycle emissions of an EV, however, studies have shown that even when charged in countries with energy grids that are highly dependent on fossil fuels, the lifecycle emissions of an EV are lower than the equivalent ICE vehicle.

This is because the combination of fossil fuel power plants and electricity transmission are still more efficient than an internal combustion engine.

Take a free online course: An Introduction to Low Emission Road Transport

Finally, EV sceptics are often concerned by the useable life of lithium-ion batteries, often based on experience with portable electronics.

The difference is that the automotive lithium-ion battery has been designed for prolonged use and they are operated to protect against degradation.

For example, hard limits are set to prevent batteries from being fully discharged and cooling systems employed to control battery temperature, both of which protect the battery cells against degradation.

This means that modern EV batteries often outlast the vehicle, and manufacturers commonly offer battery warranties – 8 years and 100,000 miles is common – which reflects the confidence they have that the battery life will be maintained; Tesla have even gone so far as to promise a “one-million-mile battery”.

Even when the battery has reached the end of its useable life in an EV – typically set at 70-80% of its original capacity – it can be repurposed for stationary battery storage purposes, which can potentially double its useable life.

Thereafter, the raw material is still expected to be of significant value and hence many companies are researching and implementing recycling systems to recover these valuable materials for new batteries.

Combined, this means that over its lifetime, an EV will have lower overall emissions than an equivalent ICE vehicle, potentially significantly lower if the comparison is done with a small vehicle with a small battery pack that is manufactured and operated using clean energy.

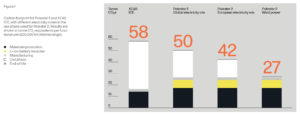

A report from Polestar (the electric brand of Volvo) compares the Polestar 2 with the equivalent ICE vehicle from its parent company, the Volvo XC40.

It shows that the even for a vehicle with a large battery the life cycle emissions can be more than halved depending on the operation:

Polestar 2 versus Volvo XC40 Lifecycle Emissions

As the grid energy used for charging becomes cleaner, the manufacturing of the vehicle and battery become a greater proportion of the total lifecycle emissions, however, in reality these contributions will also decrease as grid’s become cleaner.

Therefore, as energy systems around the world decarbonise to meet international targets for emissions reductions, electric vehicles become inherently cleaner and can become truly “zero emission”.

Get in touch to see how you can lower your emissions.